Do you ever wonder where the water you drink comes from and what measures are taken to ensure its purity? Well, one method widely employed to purify water is through the use of a water distiller. A water distiller is a remarkable device that heats water to create steam, then cools the steam to collect pure, distilled water. This process eliminates impurities, contaminants, and minerals, leaving you with clean, fresh-tasting water. In this article, we will explore the fascinating world of water distillers, their benefits, and how they work. So, get ready to quench your thirst for knowledge!

Definition of a Water Distiller

Concept of Water Distillation

A water distiller is a device that purifies water through the process of distillation. Distillation is a centuries-old method of water purification that involves heating water to create steam, capturing the steam, and then cooling it back into liquid form. This process effectively removes impurities such as bacteria, viruses, minerals, and chemicals from the water, resulting in clean and pure drinking water.

Function of a Water Distiller

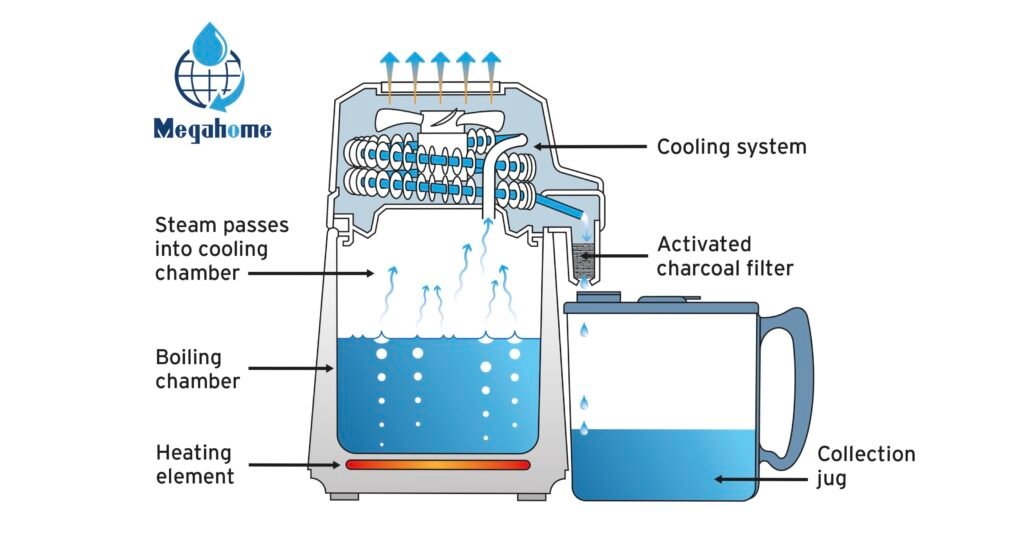

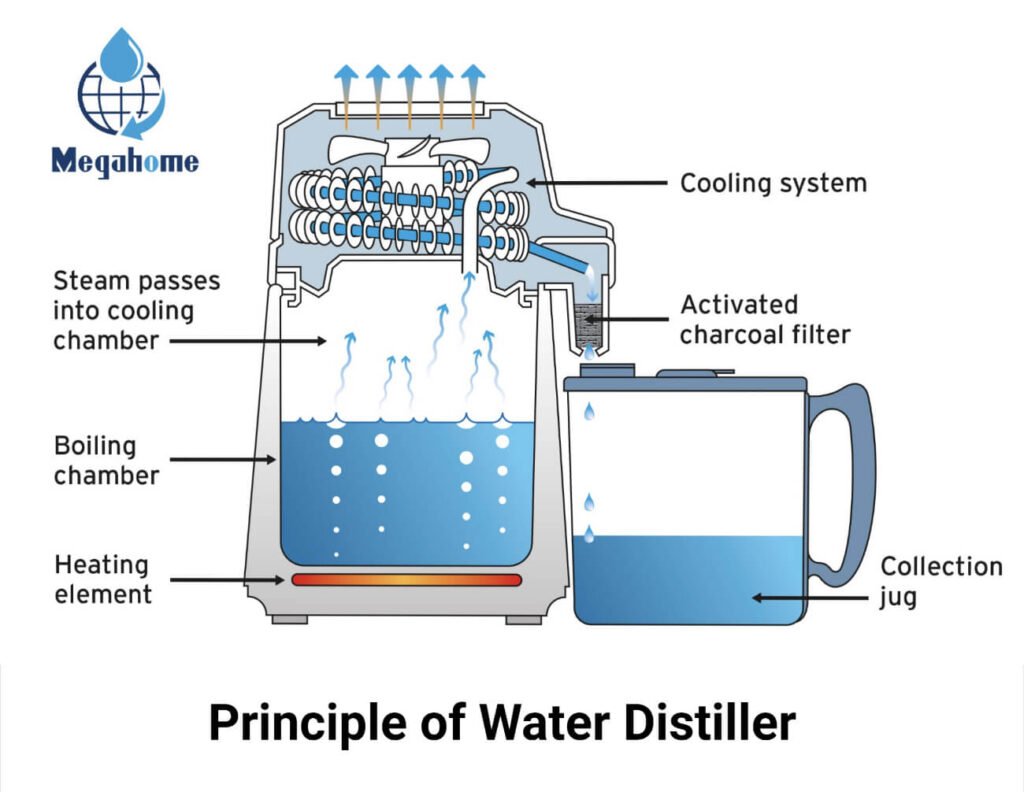

The main function of a water distiller is to produce clean and purified water by removing impurities through the process of distillation. It achieves this by heating tap water in a boiling chamber, creating steam that rises and leaves behind impurities. The steam then passes through condensing coils, where it is cooled and converted back into liquid form, resulting in pure distilled water. The distilled water is collected in a separate water collection tank, ready for consumption or further use.

Historical Context of Water Distillers

Initial Use of Water Distillers

The practice of water distillation dates back to ancient times, with evidence of distillation techniques being used by civilizations such as the Egyptians and Greeks. These early distillers used the heat of the sun to evaporate water and collect the condensed vapor, effectively separating it from impurities. This method provided a crucial source of clean drinking water, especially in areas where natural water sources were scarce or contaminated.

Evolution of Water Distillation Technology

Over the years, water distillation technology has advanced significantly, incorporating improvements in design and efficiency. With advancements in materials and engineering, traditional solar distillers have been replaced by more sophisticated distillation units. Modern water distillers now utilize electricity to heat the water and feature more efficient condensing coils, resulting in higher quality and larger volumes of distilled water.

Types of Water Distillers

Home Use Water Distillers

Home use water distillers are designed for domestic use, providing a convenient and efficient way to produce clean drinking water at home. These distillers are typically compact, countertop units that can be easily installed in a kitchen or any other suitable location. Home distillers are often designed with user-friendly controls, making them accessible to anyone seeking a reliable source of pure water.

Industrial Water Distillers

Industrial water distillers are large-scale units designed to meet the high demands of commercial and industrial applications. These distillers are capable of producing a significant volume of distilled water per day, making them suitable for large manufacturing plants, hospitals, laboratories, and other industrial settings. Industrial distillers often feature advanced automation systems for maximum efficiency and productivity.

Portable Water Distillers

Portable water distillers are compact and lightweight units that are ideal for travelers, outdoor enthusiasts, and individuals living in areas with limited access to clean water sources. These distillers are designed for easy transport and can be powered by electricity, batteries, or even solar energy, providing a versatile and portable solution for producing purified water on the go.

Specialty Water Distillers

Specialty water distillers cater to specific needs and preferences, offering unique features or focusing on particular applications. For example, some distillers are specifically designed for distilling essential oils or producing medical-grade water for use in healthcare facilities. These specialty distillers provide tailored solutions for specific industries or individuals with specialized requirements.

Components of a Water Distiller

Boiling Chamber

The boiling chamber is the part of the water distiller where the water is heated to generate steam. It is usually made of stainless steel or other materials that can withstand high temperatures. The boiling chamber often features a heating element that is responsible for heating the water, ensuring it reaches the boiling point and starts the distillation process.

Condensing Coils

The condensing coils play a crucial role in the distillation process by converting the steam into liquid form. These coils are typically made of copper or stainless steel and are designed to efficiently cool down the steam, allowing it to condense back into water. The condensed water then drips or flows into a separate collection tank, separate from any impurities left behind in the boiling chamber.

Water Collection Tank

The water collection tank is where the pure distilled water is collected and stored for later use. It is usually made of food-grade materials such as glass or BPA-free plastic to ensure the purity of the collected water. The collection tank may have a built-in dispenser or faucet for easy access to the distilled water. Some distillers also feature a carbon filter or other purification technologies integrated within the collection tank to further enhance the water’s quality.

The Process of Water Distillation

Water Heating Stage

In the water heating stage, tap water is poured into the boiling chamber of the distiller. The heating element in the chamber quickly heats the water, raising its temperature to the boiling point. As the water reaches its boiling point, steam starts to rise, leaving behind any impurities that cannot evaporate.

Vaporization Stage

During the vaporization stage, water in the boiling chamber is transformed into steam as it continues to be heated. The steam rises and travels into the condensing coils through a tube or pipe system, leaving behind contaminants and impurities that could not be vaporized.

Condensation Stage

In the condensation stage, the steam enters the condensing coils, which are typically cooled either by air or cold water. The cooling causes the steam to condense back into its liquid form, creating distilled water. The condensation process removes any remaining impurities, leaving behind only pure and clean water.

Collection Stage

The distilled water, now in liquid form, collects in the water collection tank. It is important to note that the distilled water is separated from any impurities or minerals that were left behind during the distillation process. This collection stage ensures that the water is ready for consumption or can be stored for later use, providing reliable access to purified water whenever needed.

Benefits of Using a Water Distiller

Improved Water Taste

Using a water distiller can significantly improve the taste of tap water. The distillation process removes impurities such as chlorine, minerals, and other contaminants that can affect the flavor of water. Distilled water is often described as clean, crisp, and refreshing, allowing you to fully enjoy the natural taste of water without any unwanted flavors or odors.

Removal of Water Impurities

One of the primary benefits of water distillation is its ability to remove a wide range of impurities from tap water. Distillation effectively eliminates harmful bacteria, viruses, chemicals, heavy metals, and other pollutants, ensuring that the water you consume is of the highest quality. Distilled water is free from common contaminants found in tap water, providing peace of mind when it comes to the safety and purity of your drinking water.

General Health Benefits

Consuming distilled water can offer various health benefits. By removing impurities and contaminants, distilled water reduces the burden on the body’s filtration systems, such as the kidneys and liver. Additionally, distillation removes potentially harmful substances like lead, pesticides, and chlorine, which have been linked to various health issues. Drinking pure distilled water can contribute to overall hydration and the body’s natural detoxification processes.

Potential Drawbacks of Using a Water Distiller

Energy Consumption

One of the potential drawbacks of using a water distiller is its energy consumption. The distillation process requires heating the water to boiling point, which can consume a significant amount of electricity or other forms of energy. While more energy-efficient models are available, it is important to consider the environmental impact and associated costs of operating a water distiller.

Removal of Beneficial Minerals

Water distillation removes impurities, including minerals that may have been present in the original tap water. While some minerals are essential for good health, they can also be obtained from a balanced diet. It is important to note that a varied and nutritious diet can help ensure an adequate intake of minerals, even if distilled water is consumed.

Maintenance Requirements

Water distillers require regular maintenance to ensure their proper functioning and longevity. Routine cleaning, descaling, and periodic replacement of parts like carbon filters or heating elements may be necessary. It is important to follow the manufacturer’s instructions and recommendations for maintenance to maintain the distiller’s performance and prevent any potential issues.

Potential Plastic Leaching

Some water distillers may utilize plastic components in their construction, such as tubing or collection tanks. Although manufacturers typically use food-grade and BPA-free plastics, there is still a slight possibility of plastic leaching into the distilled water over time. If this is a concern, it is advisable to choose a water distiller with minimal plastic components or opt for models with glass or stainless steel construction.

Varieties of Water Treatment Methods Compared

Water Distillation vs Filtration

Water distillation and filtration are two common methods of water treatment. While both aim to provide purified water, they approach water purification differently. Distillation involves heating water to vaporize and separate impurities, while filtration physically strains or extracts impurities through porous materials. Distillation is highly effective in removing a wide range of contaminants, including volatile organic compounds, heavy metals, and bacteria. Filtration, on the other hand, may be more suitable for removing larger particles and improving taste, but it may not be as effective in removing certain chemicals or microorganisms.

Water Distillation vs Reverse Osmosis

Reverse osmosis (RO) is another popular water treatment method that employs a semi-permeable membrane to remove impurities. Distillation and reverse osmosis both provide highly purified water, but they differ in the approach and the level of purification achieved. Distillation removes impurities through the physical separation of water molecules from contaminants, while reverse osmosis relies on selectively allowing water molecules to pass through the membrane, while blocking larger particles and molecules. Both methods have their advantages and limitations, and the choice depends on individual needs and preferences.

Water Distillation vs UV Disinfection

UV disinfection is a method of water treatment that uses ultraviolet light to kill bacteria, viruses, and other microorganisms. While effective in disinfecting water, UV disinfection does not remove dissolved solids or other contaminants. In contrast, water distillation not only removes microorganisms but also eliminates other impurities such as heavy metals, chemicals, and minerals. Distillation offers a more comprehensive purification process, making it suitable for situations where both microorganisms and other contaminants need to be addressed.

Maintenance and Care for Water Distillers

Routine Cleaning

Regular cleaning is essential to maintain the performance and hygiene of a water distiller. Most distillers come with detailed cleaning instructions, including recommended cleaning agents and procedures. Cleaning typically involves descaling the boiling chamber and condensing coils to remove mineral deposits or limescale buildup that may affect the distillation process. It is important to follow the recommended cleaning schedule to prevent any potential contamination or damage to the distiller.

Preventing Scale Build-Up

Scale build-up, also known as limescale, can occur when minerals in the water accumulate inside the distiller’s components over time. To prevent scale build-up, it is advisable to use distilled or filtered water in the distiller, especially in areas with hard water. Regular descaling using appropriate cleaning solutions or descaling agents can help remove any mineral or scale deposits that may hinder the distillation process or affect the taste of the water.

Replacing Parts

Certain components of a water distiller may require periodic replacement to ensure optimal performance. Carbon filters, heating elements, and tubing are among the parts that may need replacement over time. It is important to refer to the manufacturer’s guidelines and recommendations on when to replace these parts to maintain the distiller’s efficiency and water quality. Regularly inspecting and maintaining the distiller will help identify any worn-out or faulty parts that need replacement.

Choosing the Right Water Distiller

Understanding your Water Quality

Before choosing a water distiller, it is essential to understand the quality of your tap water. Conducting a water quality test or reviewing the water quality report provided by your local water supplier can give you insights into the impurities or contaminants present in your water. This knowledge will help you determine the type and capacity of distiller that best suits your specific needs.

Consideration of Distiller Capacity

The capacity of a water distiller refers to the volume of distilled water it can produce per day. When choosing a distiller, it is important to consider your household or business’s water consumption needs. A larger capacity distiller may be suitable for a larger family or high-demand commercial settings, while a smaller capacity distiller may be sufficient for individuals or smaller households. Choosing the right capacity ensures a constant supply of purified water without overburdening or underutilizing the distiller.

Budget Considerations

Water distillers vary in price depending on their capacity, features, and brand reputation. It is important to establish a budget range that aligns with your needs and preferences. Consider the long-term savings of producing your own distilled water versus the cost of purchasing bottled water or utilizing other water treatment methods. A higher initial investment in a quality distiller can often result in cost savings and convenience in the long run.

Brand Reputation and Reviews

Researching and considering the reputation of the distiller brand is crucial in ensuring the quality and reliability of the product. Reading customer reviews, testimonials, and endorsements can provide valuable insights into the durability, performance, and overall satisfaction levels of users. Reputable brands with positive customer feedback are more likely to provide reliable and well-built distillers that meet your expectations.

Warranties and After-sales Service

Checking the warranty coverage and after-sales service provided by the distiller manufacturer is important for peace of mind and customer support. A comprehensive warranty ensures protection against potential manufacturing defects or malfunctions, while reliable after-sales service ensures prompt assistance in case of any issues or queries. Be sure to review the warranty terms and conditions to understand what is covered and how to access support when needed.