Imagine having access to pure, crystal-clear water right in the comfort of your own home. Sounds appealing, right? Well, the good news is that with a home water distiller, you can make this a reality. But how does it actually work? A home water distiller is a remarkable device that utilizes a process called distillation to purify water. By heating the water to its boiling point, the impurities and contaminants are left behind as steam, while the clean, condensed water vapor is collected for consumption. In this article, we will explore the intricacies of how a home water distiller works and why it is becoming an increasingly popular choice for individuals seeking pure drinking water. Prepare to be amazed by the wonders of this innovative technology!

Understanding the Concept of Water Distillation

Definition of Water Distillation

Water distillation is a process that involves boiling water to create steam, and then condensing the steam back into water. This method of purification effectively removes impurities and contaminants from the water, resulting in water that is safe to drink and use in various applications.

The Role of Distillation in Water Purification

Water distillation plays a crucial role in water purification by eliminating a wide range of impurities. It is particularly effective in removing heavy metals, chemicals, bacteria, viruses, and other harmful substances that may be present in water. Distillation works by separating the water from these impurities through the process of evaporation and condensation, resulting in cleaner and purer water.

The History of Water Distillation

The concept of water distillation has been around for centuries and has been used by different civilizations throughout history. The ancient Greeks and Romans used distillation as a means of purifying water and producing essential oils. In more recent times, distillation has been widely adopted for industrial purposes and household water purification. Today, home water distillers offer a convenient and efficient way for individuals to enjoy the benefits of distilled water right in their own homes.

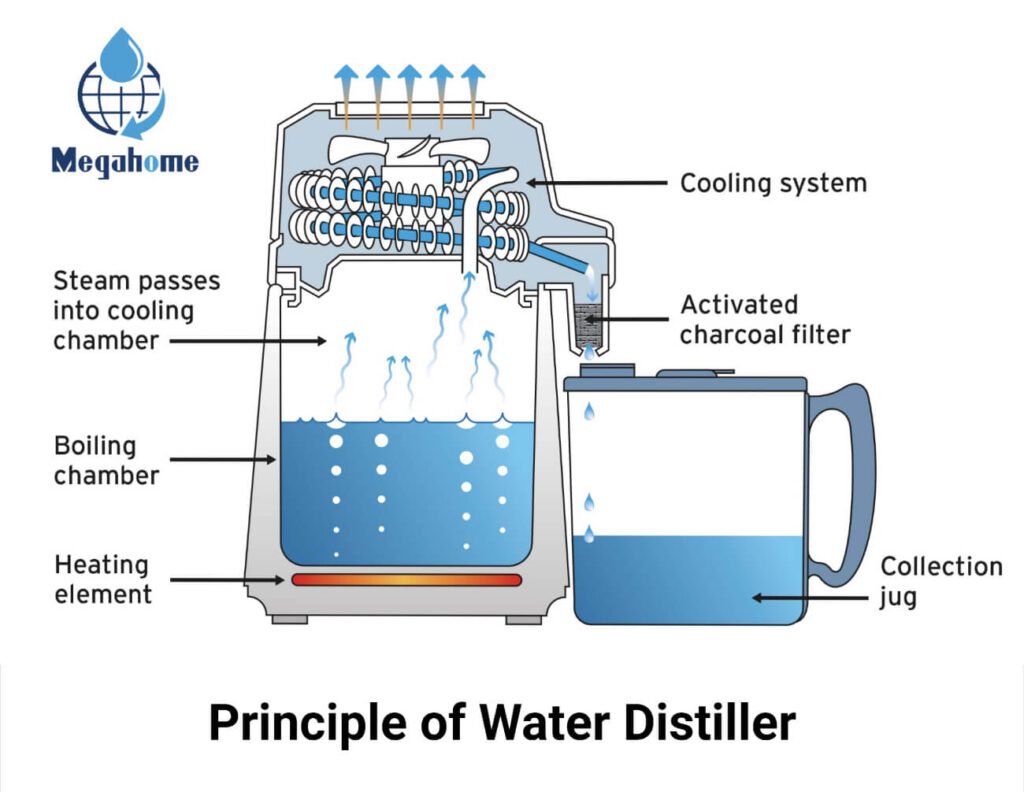

The Main Components of a Home Water Distiller

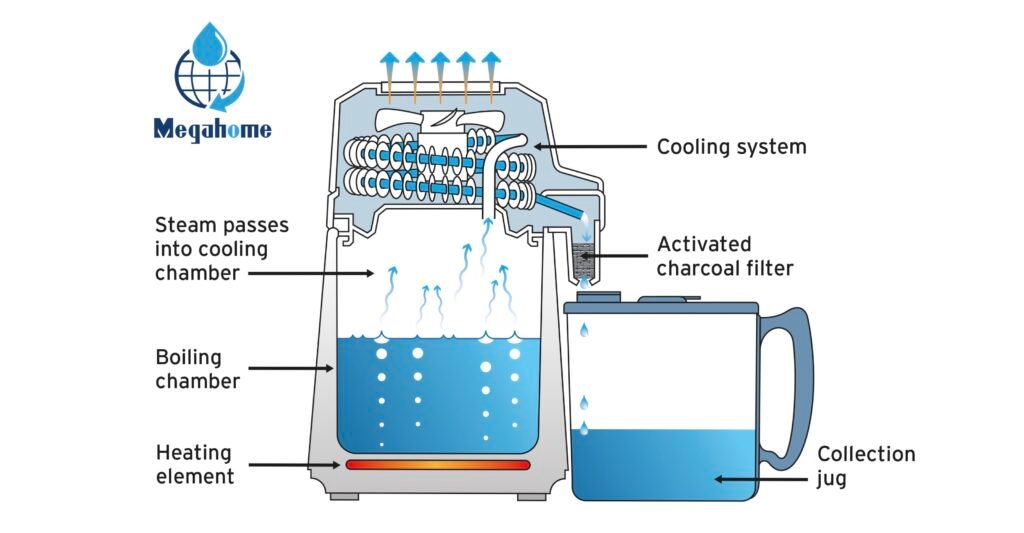

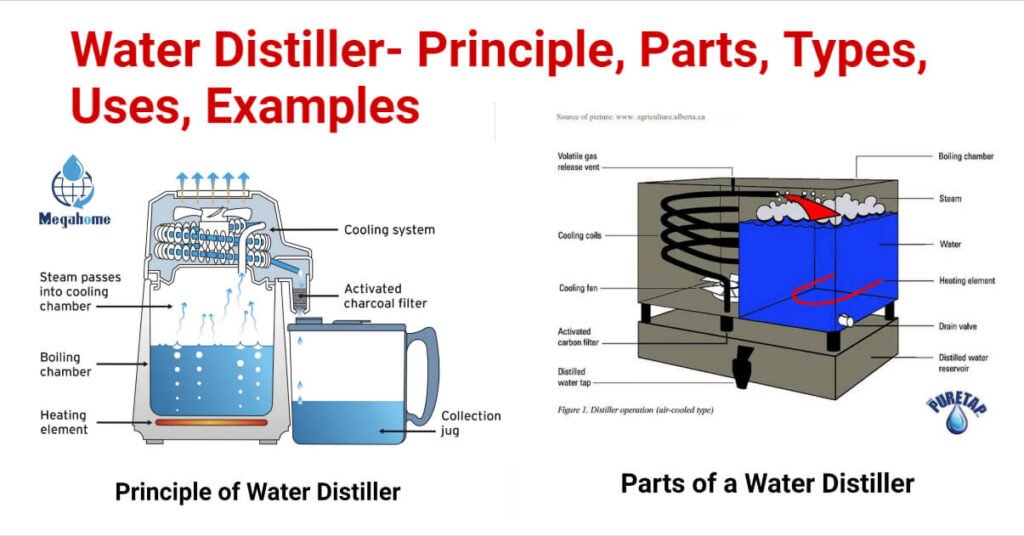

Water Reservoir or Boiler

The water reservoir, also known as the boiler, is a vital component of a home water distiller. It is where the water is initially loaded and heated to start the distillation process. The reservoir is typically made of stainless steel or glass to ensure durability and prevent any potential contamination of the distilled water.

Heat Source

The heat source in a home water distiller is responsible for heating the water in the reservoir to its boiling point. This can be achieved through various methods, such as electric heating elements or gas burners. The heat source is an essential component as it initiates the process of evaporation, where the water is converted into steam.

Condenser

The condenser plays a crucial role in the distillation process by converting the steam back into water. It consists of a coiled tube that is cooled, either by ambient air or running water, to facilitate condensation. As the steam passes through the condenser, it loses heat and transforms into liquid water, ready for collection.

Collection Vessel

The collection vessel is where the distilled water is collected after condensation. It is typically a separate container from the water reservoir and is designed to hold the purified water safely. Some distillers may also have a dispensing feature, allowing for convenient access to the distilled water for immediate use.

Additional Components – Charcoal Filters and Mineral Filters

Some home water distillers may also include additional components, such as charcoal filters and mineral filters. Charcoal filters help to further purify the distilled water by removing any residual odors, tastes, or volatile organic compounds. Mineral filters, on the other hand, add beneficial minerals back into the distilled water, enhancing its taste and nutritional value.

The Process of Home Water Distillation

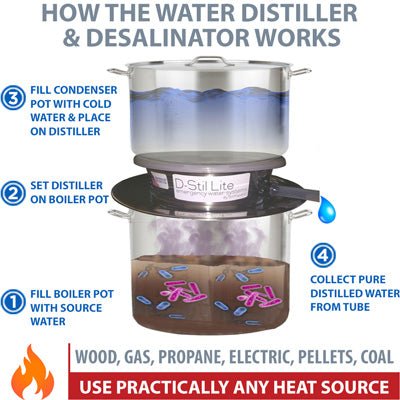

Loading of the Water Reservoir

To begin the distillation process, you will need to load the water reservoir with tap water. It is essential to use clean, potable water for optimal results. Fill the reservoir to the recommended level, ensuring not to overfill it.

Heating and Evaporation

Once the water reservoir is loaded, the heat source is activated to heat the water. As the temperature rises, the water reaches its boiling point and begins to evaporate, turning into steam. During this process, impurities and contaminants in the water are left behind, as they cannot vaporize and remain in the reservoir.

Condensation and Collection

As the steam rises from the water reservoir, it travels into the condenser, where it encounters a cooler environment. This causes the steam to lose heat rapidly and transform back into liquid water through condensation. The condensed water then drips down the coiled tube and collects in the designated collection vessel, ready to be consumed or used for various purposes.

Additional Filtration Process

Some home water distillers incorporate additional filtration processes after condensation. This may involve passing the distilled water through charcoal filters or mineral filters. The charcoal filters help to improve the taste and odor of the distilled water by removing any residual impurities. Mineral filters, on the other hand, add back essential minerals that may have been lost during the distillation process.

The Role of Heat in Water Distillation

Water Boiling Point

The boiling point of water is the temperature at which it changes from a liquid to a gas or vapor state. At sea level, water boils at approximately 100 degrees Celsius or 212 degrees Fahrenheit. When the water reaches this temperature, it evaporates and turns into steam, leaving behind impurities and contaminants.

Heat and Evaporation

Heat is a critical factor in the distillation process as it provides the energy required to convert water into steam. By applying heat to the water reservoir, the temperature rises, and the water molecules gain enough energy to break their bonds and change phase. This results in the evaporation of water and the separation of impurities.

Regulation of Heat in Distillers

Home water distillers typically include mechanisms to regulate and control the heat during the distillation process. This ensures that the water is heated to the proper temperature for evaporation while preventing excessive heat that may damage the distiller or affect the quality of the distilled water. These heat regulation mechanisms contribute to the efficiency and safety of the distillation process.

The Role of Condensation in Water Distillation

Role of a Condenser

The condenser plays a crucial role in the water distillation process by facilitating the conversion of steam back into liquid water. As the steam travels through the condenser, it encounters a cooler environment, causing it to lose heat rapidly. This cooling effect results in the condensation of the steam into liquid water, which can then be collected for use.

Conversion of Steam to Water

When steam enters the condenser, the surrounding cool temperature causes the vapor molecules to lose energy. As a result, they slow down and come closer together, forming liquid water droplets. This transformation from steam to water occurs as the steam gives off its latent heat to the condenser, allowing it to condense.

Collection of Distilled Water

After condensation, the liquid water drips down the coiled tube of the condenser and collects in the designated collection vessel. This distilled water is now free from impurities and contaminants that were present in the original water. The collection vessel provides a safe and convenient storage space for the purified water, ready to be used for drinking or other applications.

Further Filtration in Home Water Distillers

Use of Charcoal Filters

Some home water distillers incorporate charcoal filters as an additional step in the purification process. These filters help to improve the overall taste and odor of the distilled water by removing any residual impurities. The charcoal’s porous structure allows it to effectively adsorb and trap substances, such as chlorine, volatile organic compounds, and certain heavy metals, further enhancing the water’s quality.

Importance of Post-Distillation Filtration

While distillation effectively removes a wide range of impurities, including bacteria, viruses, and chemicals, additional filtration processes can further enhance the water’s purity. Post-distillation filtration, such as the use of charcoal filters or mineral filters, helps to eliminate any remaining contaminants and improve the taste and quality of the distilled water.

Replacement and Maintenance of Filters

When using a home water distiller with additional filtration components, it is essential to monitor and replace the filters regularly. Over time, the filters may become saturated or clogged with impurities, reducing their effectiveness. Following the manufacturer’s recommendations for filter replacement and maintenance ensures that the home water distiller continues to produce high-quality, purified water.

The Quality of Distilled Water

Taste of Distilled Water

Distilled water has a pure, clean, and neutral taste due to the removal of impurities during the distillation process. Many people find the taste of distilled water to be refreshing and enjoyable, as it does not contain any residual flavors or odors. The absence of minerals and other substances in distilled water contributes to its clean and crisp taste.

Removal of Contaminants

Distillation is an effective method of water purification that removes a wide range of contaminants from the water. It eliminates bacteria, viruses, chemicals, heavy metals, and other impurities that may be present. By boiling the water and converting it into steam, distillation separates these contaminants, leaving behind clean, purified water.

Loss of Minerals and its Implications

While distillation removes impurities, it also removes beneficial minerals present in the water. The distilled water does not contain the minerals typically found in tap or natural spring water, such as calcium, magnesium, and potassium. While the loss of minerals through distilled water consumption is minimal and can be supplemented through a balanced diet, some individuals prefer water with mineral content for its potential health benefits.

The Efficiency of Home Water Distillers

Energy Consumption

Home water distillers vary in their energy consumption depending on their design and features. However, distillation generally requires a significant amount of energy due to the heating process. It is important to consider the energy efficiency of a distiller when choosing one for your home. Look for models that have energy-saving features or certifications to ensure minimal energy usage.

Quantity of Distilled Water

The quantity of distilled water produced by a home water distiller depends on its size and capacity. Smaller distillers typically produce around 1 gallon (3.78 liters) of distilled water per cycle, while larger models can produce several gallons. It is important to assess your water needs and choose a distiller that can meet your daily requirements.

Time Taken for Distillation

The time taken for distillation depends on the design and performance of the home water distiller. The heating and boiling process, as well as the condensation and filtration steps, can vary in duration. Generally, distillation can take several hours to complete a full cycle, including heating, condensation, and additional filtration. It is crucial to plan accordingly and allow sufficient time for the distillation process.

Maintenance of Home Water Distillers

Cleaning the Water Reservoir

Regular cleaning of the water reservoir is important to maintain the cleanliness and performance of the home water distiller. Follow the manufacturer’s instructions for cleaning and disinfecting the reservoir to prevent the buildup of contaminants or mineral deposits. Proper maintenance ensures the longevity and efficiency of the distiller.

Servicing the Heat Source

The heat source of a home water distiller, whether it is an electric heating element or a gas burner, requires periodic servicing to ensure optimal performance. Regular maintenance may involve cleaning, inspection, or replacement of the heat source components if necessary. It is essential to follow the manufacturer’s guidelines and recommendations for servicing to maintain the distiller’s functionality.

Maintaining the Condenser

Proper maintenance of the condenser is crucial for efficient distillation. Regular cleaning and inspection of the condenser tubes or cooling mechanism help prevent clogs or obstructions that may affect the condensation process. Check for any signs of damage or wear and promptly address any issues to ensure the distiller functions effectively.

Replacing Filters

If your home water distiller has additional filtration components such as charcoal filters or mineral filters, it is important to replace them regularly. Over time, these filters become saturated or clogged with impurities, reducing their effectiveness. Follow the manufacturer’s guidelines for filter replacement frequency to maintain the quality of the distilled water.

Factors to Consider when Buying a Home Water Distiller

Size of the Distiller

Consider the size of the home water distiller based on your water consumption needs. Smaller distillers are suitable for individuals or small households, while larger distillers are more suitable for larger families or commercial use. Select a size that can meet your daily requirements without wasting excess energy or resources.

Energy Efficiency

Look for energy-efficient home water distillers that consume minimal energy while still providing optimal performance. Energy-saving features, such as automatic shut-off or low-power modes, can help reduce electricity usage and save costs in the long run. Energy efficiency is not only beneficial for your pocket but also promotes environmental sustainability.

Ease of Maintenance

Consider the ease of maintenance when choosing a home water distiller. Opt for models that have user-friendly features, such as easy-to-clean reservoirs or removable filters. A distiller that is simple to maintain will save you time and effort in the long term, ensuring its longevity and efficient operation.

Additional Features – Automatic shut-off, digital display, etc.

Some home water distillers may come with additional features that enhance convenience and usability. These features can include automatic shut-off when the distillation process is complete, digital displays for easy monitoring, or programmable settings. Assess which features are essential for your needs and choose a distiller that offers them.

In conclusion, understanding the concept of water distillation is essential for those seeking a reliable and efficient method of purifying their drinking water. Home water distillers offer individuals the convenience of producing distilled water right in their own homes. By comprehending the main components, the process, and the role of heat, condensation, and further filtration, individuals can make informed decisions about the quality, efficiency, and maintenance of their chosen home water distiller. Consider factors such as size, energy efficiency, ease of maintenance, and additional features when purchasing a home water distiller to ensure the best fit for your needs. By harnessing the power of distillation, you can have access to clean and purified water, contributing to your overall well-being and peace of mind.